Machining

This tutorial explains how to place a machining between two beams.

Generalities:

Placing a machining is done on the same way as placing an accessory or hardware

Select the profile you want to machine

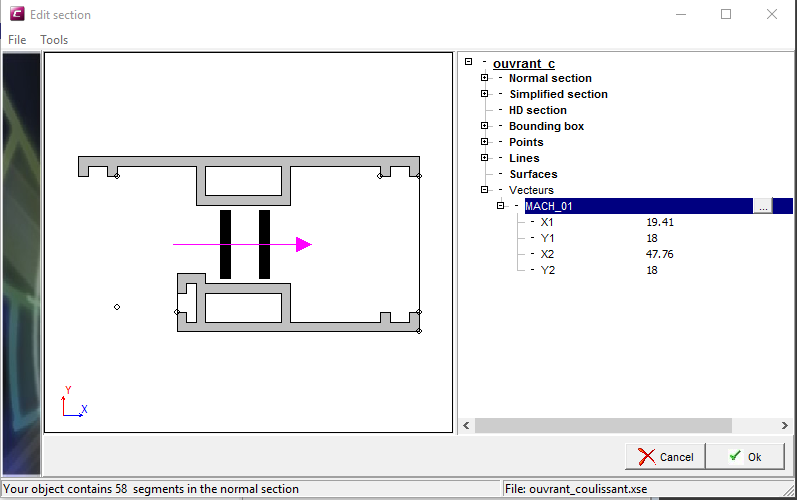

- Right click on the vector menu

-Add a vector with the arrow button

-Define a vector- Position (1)

- Length (2)

- Direction (3)

-

Name the vector

-Give a new name

or

- Use the drop down menu to select an existing name

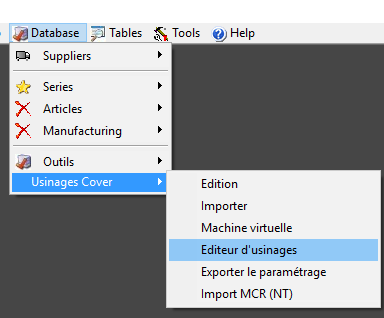

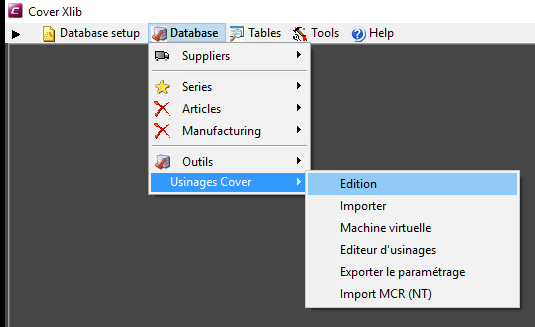

In the database menu

- Select machining editor

-

Name the job

and validate with the pen

-

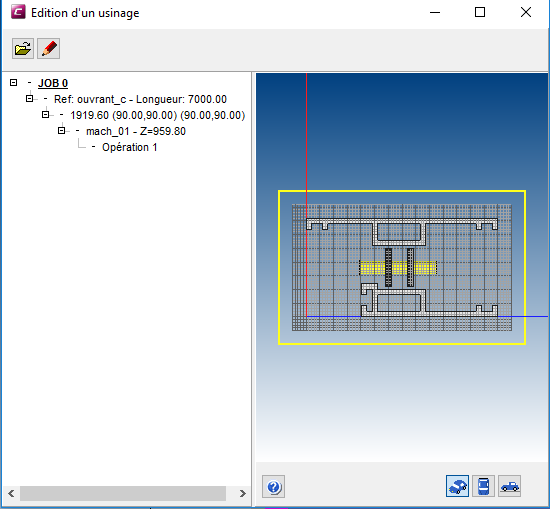

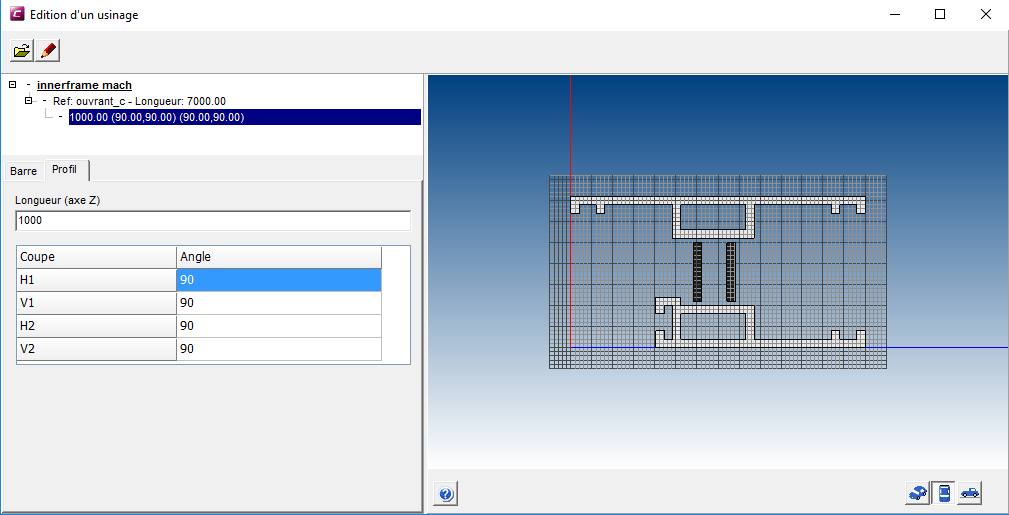

Right click – add a beam

- Select the beam line - Right click - add a profile

- Select the profile line - Right click - add a machining

- Name the machining

-

Select the machinig - Right click - add an operation (You can add as many as you wish)

- Select the type of operation

- Hole

- Slot

- Rectangle

- Cylinder

- Macro

- Select the vector and define the position

(The pink rectangle represents the axis of the machining)

- Valid with the “red pen button”

In the database menu

- Select edition

-

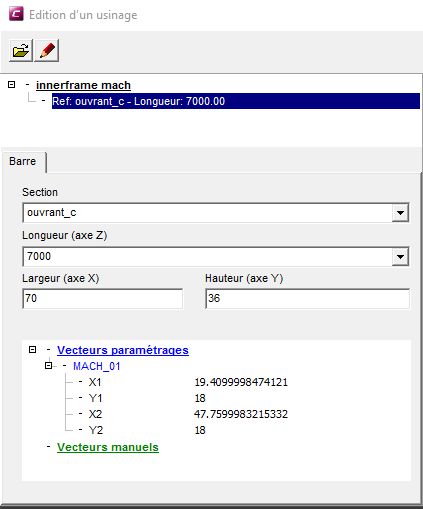

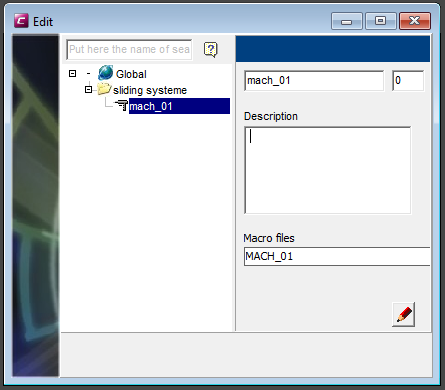

Add a group

- Name the group

- Add an object

- Name the object

- Click on the folder button

- Select the machining

- Valid with the red pen button

The first part is done.

There are different ways (different actions) to place a machining (like there are different ways to place an accessory or hardware (on node, on profile extremity…)

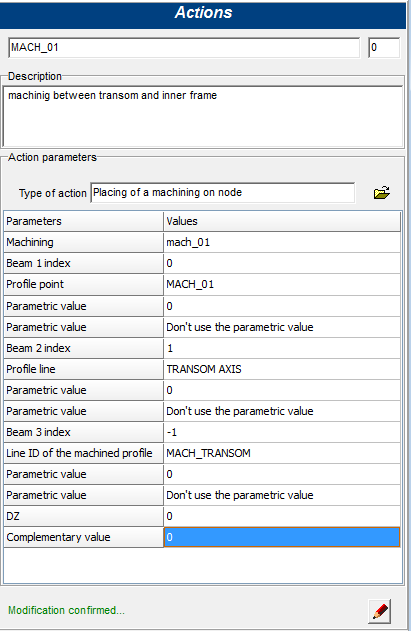

In this example we want to place a machining on the inner frame at the height of the transom. Now we are going to place the machining on the node :

Add an action type “Placing of a machining on node”

- Machining: select the machining

- Beam 1 index: identification in the node of the reference bar for positioning machining (in this example the inner frame)

- Profile point: point on a profile on beam with index 1.

- Parametric value (optional): parametric value of the profile on beam 1 index

- Beam 2 index: identification in the node of the reference bar for positioning machining (in this example the transom)

- Profile line: line on a profile on beam with index 2 (in this example the axis of the transom).

The intersection between the point (c) and the line (f) determines the insertion point of the machining.

-

Parametric value (optional): parametric value of the profile on beam 2 index

-

Beam 3 index (optional): default value -1

-

Line ID of the machining profile: identification line in the machined profile

-

Parametric value:

-

DZ: movement relative to the calculated point along the Z axis

-

Complementary value: not used

Place the action in the node procedure.

- Refresh the project

- Select the profile on the technical mode

- Right click and see the machining to control (never click on the red pen button)